The chips that power our cars

Semiconductors have already become a crucial part of today’s cars. But they’ll gain even greater importance in the future. Let’s have a look at how they’ll enable functions like self-driving or immersive infotainment.

One thing we all know about semiconductors is that they’ve been scarce over the past few years. Everywhere. From dishwashers to credit cards and cars. Expressions like ‘semiconductor shortage’ and even ‘chip wars’ have therefore found their way into our daily news feeds.

But looking beyond the supply chain crunches. why are these tiny pieces of electronic hardware so crucial in the first place – especially for our cars?

First of all, cars are undergoing greater and greater electrification and digitalization, from electric drive trains to immersive infotainment systems in the cockpit. Vehicles are now software-defined. And all this software runs on computers, scattered throughout the vehicle.

What’s a semiconductor?

In order to process calculations and computations, computers rely on integrated circuits – scaled-down versions of electronic circuits. These route all the information and tasks through the central processing unit (CPU), memory and other building blocks. Integrated circuits are made from silicon – an element that can act both as a conductor or insulator for electric current, hence the name semiconductor. This makes it the most valuable part of the computer, since semiconductors can act as transistors – turning the current on and off just like an electrical switch.

‘Integrated circuit’ (ICs), ‘SoC’ (’System on a Chip’) and ‘microchip’ are essentially synonyms for the same thing: a mostly silicon-based processing unit for information that runs all our electronic devices today.

During production, hundreds of microchips are manufactured on wafers – silicon discs that look and feel very similar to CDs but have the size of about an LP. Each of these microchips can contain billions of single transistors.

Why are chips important for cars?

As with any electronic device, cars rely on chips to power their functions. A car can contain over a thousand of these essential chips, spread across all areas of the vehicle. Think about the sensor that detects a crash and activates the life-saving airbag. That process is based on semiconductors. And there are more safety-critical applications relying on semiconductors, such as ESC (Electronic Stability Control) to reduce skidding, to name just one example. Even basic functions like controlling your rearview mirror, opening the trunk automatically and unlocking your car remotely via a smartphone or key. All of these are based on semiconductors.

Wafer with a 30cm diameter that contains hundreds of automotive chips

Wafer with a 30cm diameter that contains hundreds of automotive chips

Of course, chips have been around for a while. The first integrated circuit was introduced by Jack Kilby in the middle of the 20th century. His invention earned him the Nobel Prize for Physics – and revolutionized the electronics industry.

Nowadays, high-end chips can be found in common consumer devices such as smartphones. And we've become accustomed to the fact that their capacity and performance is increasing at a rapid pace.

But when developing the future of mobility, it’s not as simple as taking these existing chips and putting them in the car. So, what’s so special about automotive semiconductors in particular? What sets them apart from the kind you would find in your smartphone? Perhaps the greatest differentiation lies in their extraordinary durability.

How chips for cars and smartphones differ

Semiconductors in cars and those in consumer devices vary with regard to their quality and operational requirements. As they are used in safety-critical situations, automotive semiconductors are subject to much stricter specifications. They must be guaranteed to function over the course of 15 years, with failure rates tending to zero. Much lower than those of chips in phones and laptops.

For automotive applications, semiconductors, which are already very fragile and sensitive components, must be able to cope with extreme environmental conditions. This includes resistance to humidity and vibration. This is a must, as cars are not only built to last on smooth highways, but also on rough roads and even other terrain. In the case of semiconductors for consumer devices, this level of robustness isn’t a requirement. Additionally, automotive chips must be able to withstand and continue to function flawlessly in very low as well as very high temperatures – between -40 and +150°C in some cases, to be precise.

To put this into perspective, imagine this: you’re in Death Valley at the peak of summer. The extremely hot climate causes a semiconductor in your phone to overheat, automatically shutting down the entire device. In a car, that’s not an option. All semiconductors must be able to handle the heat in order to ensure that driving functions perform safely and reliably.

To guarantee this exceptionally high level of durability and reliability, automotive semiconductors undergo a rigorous manufacturing and testing process. But it comes with a drawback: the most cutting-edge chips are usually unfit for these kinds of conditions – and cannot pass these tests.

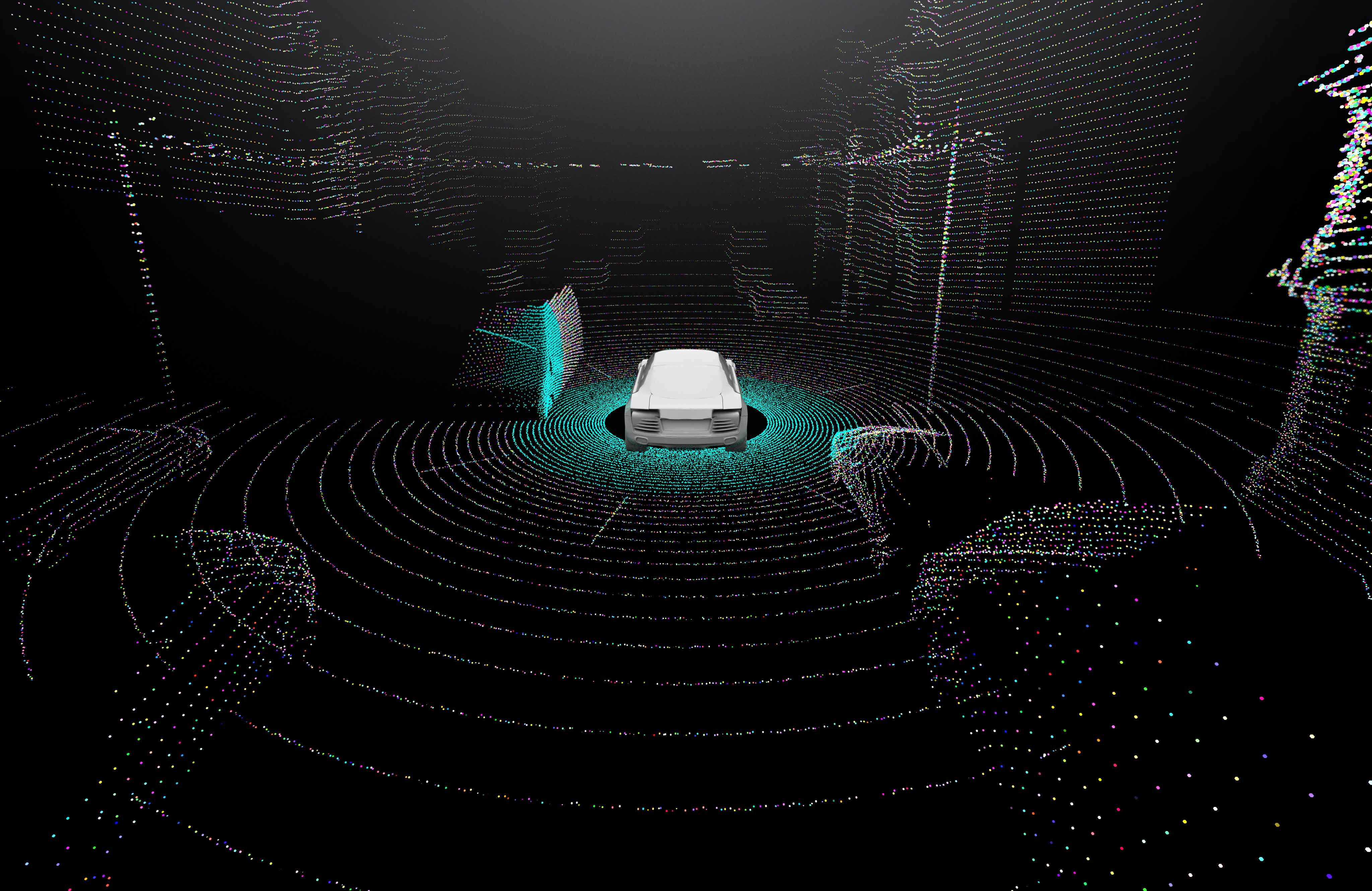

That’s why we haven’t seen high-performing chips in cars for a long time. Semiconductor and hardware development teams at CARIAD are working intensively with our partners like STMicroelectronics and Qualcomm to ensure automotive robustness for the latest cutting-edge ICs as well. After fulfilling that precondition, those semiconductors will begin to find their way into our vehicles. And we’re very excited for the potential that they bring with them. It’ll allow for more streamlined electronics architectures within the cars, ultimately being powered by only one high performance computer. What’s more, the cutting-edge semiconductors will form the basis of automated driving functions and a seamless digital experience. Because the more powerful the chips, the more ambitious our software can be.